The Report contains consolidated data on TVEL Fuel Company, and in certain cases, where necessary, discloses the data on each separate company.

* According to the Clause 1 of the Article 4.2 of the Federal Law No. 7-FZ "On Environmental Protection" d/d January 10, 2002.

Energy Saving and Efficiency Improvement Program

The project on energy consumption reduction and energy efficiency improvement of industrial companies of ROSATOM is of great importance for the nuclear industry competitiveness recovery.

TVEL Fuel Company is one of the leaders in introduction of automated systems for accounting of energy resources and methods to improve energy efficiency in the nuclear industry, including processes of energy inspections, formation of long-term investment, organizational and technical programs and specific activities for energy efficiency. The Company's enterprises are involved in Energy Saving and Efficiency Improvement Program (further "the Program") since 2011. The Program was approved subject to the results of energy and thermovisional inspections held at the Company's organizations.

The representatives of TUV International Certification LLCA carried out regular witness audit of Energy Management Corporate System (EMCS) at TVEL JSC and its subsidiaries. No deviations and discrepancies were revealed. In 2017, the Company's enterprises were also audited by the auditors of TVEL JSC.

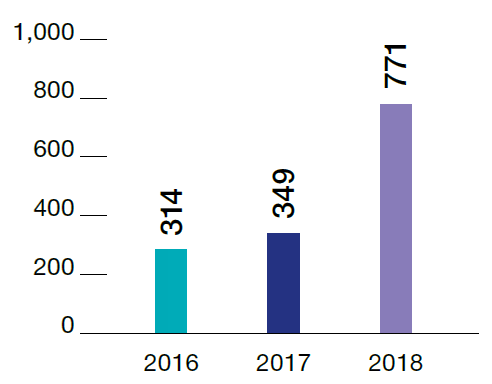

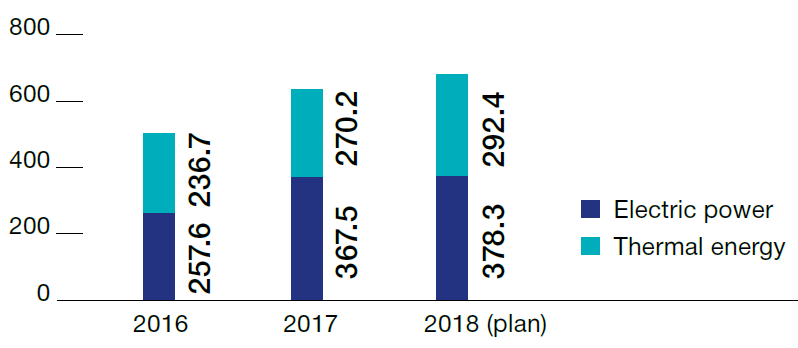

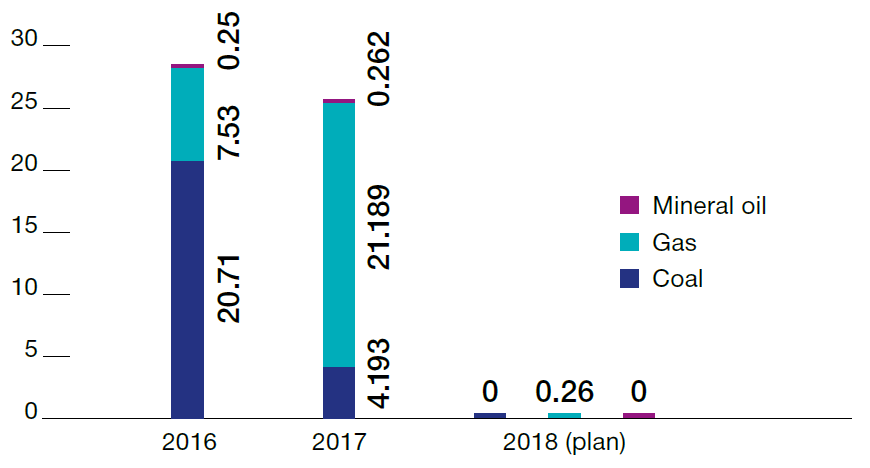

Diagram 40

* The targeted growth of financing is explained by participation of each and every enterprise of TVEL Fuel Company in the Program events since 2017.

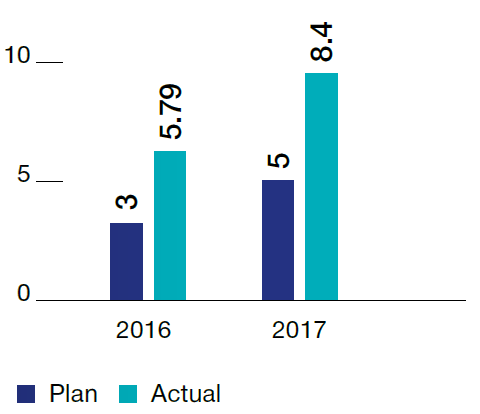

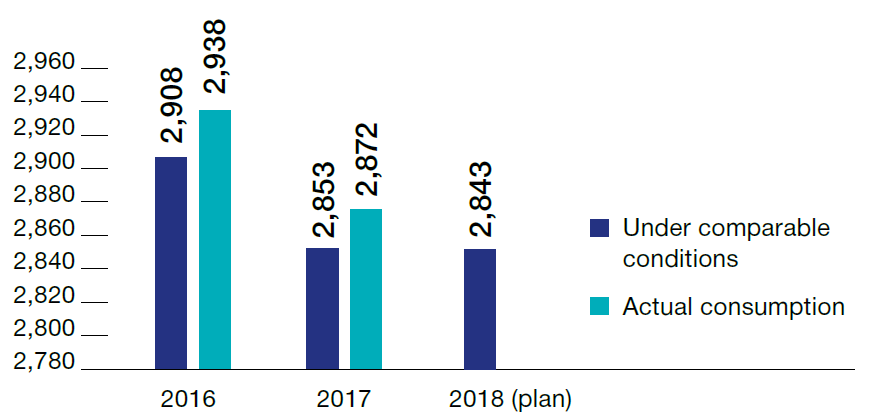

Diagram 41

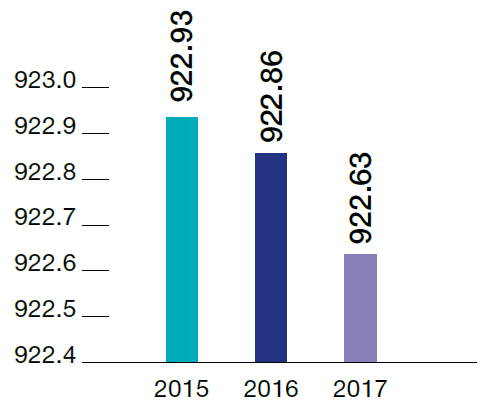

The Program has established target values for reduction of energy consumption (as compared to the reference year 2015) in monetary terms. In 2017 the target indicator of energy resources consumption was 5%. As a result of the implemented activities this value was achieved and even surpassed.

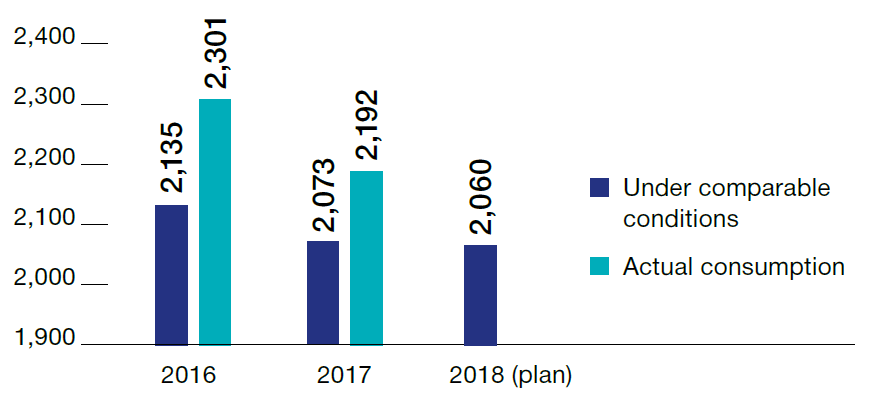

In 2017, the energy consumption by the Company's enterprises was reduced by 5.67%, heat energy - by 11.5% as compared to the reference values of 2015 under comparable conditions*. The reduction in energy resources consumption (as compared to 2015) in monetary terms was 8.4% (RUB 834 mln).

Diagram 42

Diagram 43

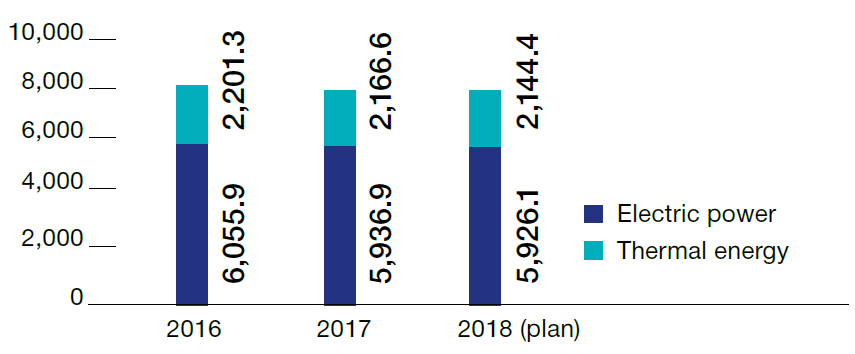

Diagram 44

Diagram 45

Diagram 46

* Including generation of electricity and thermal energy by HPPs at TVEL Fuel Company´s subsidiaries. In 2017, HPPs at ChMZ JSC and UEIP JSC were taken over by OTEK JSC; in 2018, HPPs at SGChE JSC will also be taken over. In 2017, OTEK JSC was procuring coal for HPP at SGChE JSC.

Change in the structure of fuel consumption in 2017 was caused by the use of gas instead of goal by HPP at SGChE JSC. Estimated consumption in 2018 is stipulated by the fact that starting from January 1, 2018 all HPPs of TVEL Fuel Company were excluded from the perimeter of the Company

Table 62

Indicator | 2016 | 2017 | 2018 (plan) |

|---|---|---|---|

Total amount of saved electric power, mln kWh | 118.4 | 171.53 | 181.493 |

Total amount of heat energy, thous. Gcal | 206.9 | 268.8 | 280.97 |

Total amount of electric power and heat energy, thous. GJ | 1291.7 | 1742.9 | 1829.7 |

Results 2017:

- Creation of the circulating water supply system on the base of existing hydrotechnical structures of AECC JSC:

- replacement of energy-intensive pump 12 NDS TOU-4 of building 803 with less powerful pump D500 made it possible to save annually 489.9 thous. kWh;

- pre-test assembly of NK-2 (fixed cascade) without OK-2 (refining cascade) made it possible to save annually 576 thous. kWh;

- Optimization of industrial water and air supply system of PA ECP JSC;

- Modernization of refrigeration supply and conditioning system of PA ECP JSC: refrigeration supply scheme of building 901 was upgraded with two new refrigerating machines that are more energy-efficient by 20% than the machines in operation; 10 of 16 refrigerating machines were updated; energy consumption of refrigerating machines was reduced by 31%. Besides, enhanced management and automation system was introduced; it enables management of equipment refrigeration process almost without human involvement. Total economic benefit of these activities will amount to at least RUB 3 mln per annum;

- Modernization of general and gas-cleaning ventilation systems of PA ECP JSC;

- Reconstruction of sanitary sewer system of NCCP PJSC ensured meeting the target values of water consumption and runoff from - 29.6% in 2016 to 5.5% in 2017 as compared to 2015. Following the results 2017, as compared to 2016, the funds in the amount of RUB 23.84 million were saved by preventing penetration of ground water, defrost water and rain water to bitumen compound storage facility, as well as by reduction of charges for excess of threshold limit value;

- Decentralization of air supply system of SGChE JSC;

- Decommissioning of Technological Control Objects No. 7 and 8, which made it possible to save electric power and deaerated water at SGChE JSC;

- Extension of temperature range for operational parameters of gas centrifuges in summer time, and, consequently, change in operating mode of refrigeration equipment of building 34 of SGChE JSC;

- Change in heating scheme of reactor plant and radiochemical plant (relocation of pump station of Fire Pumphouse of building 475 beyond the area of reactor plant of site 11 of SGChE JSC);

- Reduction of costs for dilution of condensed water with domestic and drinking water at SGChE JSC;

- The system of frequency-controlled drives of equipment cooling pumps of Technological Control Objects No. 64 and 65 of UEIP JSC was made automatic. The application of this system results in electrical energy saving for at least 3 mln kWh per annum.

- Structure 715 at ChMP JSC became weather-resistant. Due to stained-glass glazing of the building in 2017, nearly RUB 4 million were saved, or RUB 8 million on an annual basis.

- The power transformers at MSZ PJSC were replaced.

Plans 2018:

- Modernization of heating system at AECC JSC;

- Optimization of industrial pump station (installation of low-pressure impeller) at PA ECP JSC;

- Replacement of refrigerating machines at UEIP JSC;

- Completion of decentralization of the compressed air supply system at MSZ PJSC;

- Modernization of general lighting network (including replacement of lamps with LEDs) at ChMP JSC;

- Installation of circulating pumps in heating systems of buildings at Centrotech SPA LLC;

In December 2017, the author team consisting of employees of UEIP JSC – Klyushin A.A., Lobov A.G., Fukalov A.I., Khramov V.V. – was given the Corporate Award in nomination "Best Engineering and Process Solution" for the project "Technical Upgrading of Supervisory Control System of Building 3001, Shop 53". The project authors were awarded the 3rd class diplomas.

Due to their great expertise the team members managed to minimize costs and to reduce capital expenses by RUB 166.9 million (survey and design - RUB 13 mln, construction and installation - RUB 55.5 mln, equipment - RUB 80.2 mln, pre-commissioning - RUB 18.2 mln) and operational expenses by RUB 108.2 thous. per annum.

Use and Processing of Materials

The quantity of materials necessary for the manufacture of products at enterprises of the Company is determined by the production program.

Enterprises of separation-sublimation complex use uranium and synthetic materials for products manufacturing. Enterprises of fabrication block use raw materials represented by enriched uranium product. Synthetic materials, ferrous and non-ferrous metals are basically used in the manufacture of gas centrifuges.

All raw materials used by TVEL Fuel Company enterprises are purchased. No renewable materials are used in production. Examples of the used materials are shown in Table below.

Table 63

Material | 2015 | 2016 | 2017 |

|---|---|---|---|

Sulfuric acid | 1171 | 713 | 735 |

Technical sulfuric acid (oleum) | 12005.2 | 12247.2 | 12664.87 |

Nitric acid | 11859.6 | 18584.7 | 22494.6 |

Hydrochloric acid | 7260.6 | 5649.0 | 7093.1 |

Ferrous metals | 2385.0 | 2112.0 | 2358.5 |

Non-ferrous metals | 786.2 | 834.9 | 846.1 |

* Use of materials for main production by TVEL FC Enterprises, tons

Industrial and Consumer Waste Disposal

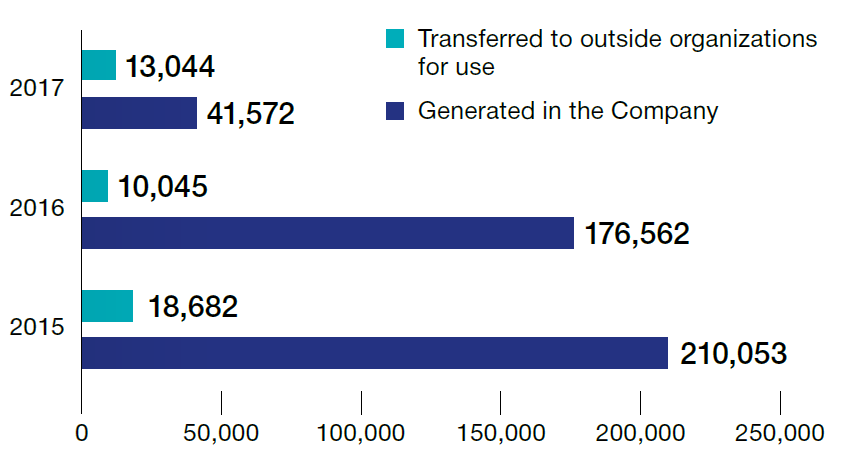

In 2017, the total amount of industrial and consumer waste of the Company was decreased by 76.5% as compared to the level of 2016 and made around 41.6 thous. tons.

Main reasons of waste formation decrease in 2017:

- Reduction of hazard class 5 (slightly hazardous) waste (ashes and slag) generation due to reduction of coal burning by HPP (Seversk Branch of OTEK JSC) and reorganization of waste calculation*.

- Reduction of generated at UEIP JSC waste and scrap containing uncontaminated ferrous metals due to the fact that there was no need for replacement of the existing process equipment.

* In 1st - 3rd quarters of 2017 SGChE JSC accounted for all wastes generated in the process of production economic activity of HPP at OTEK JSC; since the fourth quarter of 2017 HPP at OTEK JSC began to account for the generated waste independently.

Table 64

Enterprise | 2015 | 2016 | 2017 |

|---|---|---|---|

ChMP JSC | 32% | 135% | 11% |

NCCP PJSC | 1% | 0% | 0% |

MSZ PJSC | 66% | 56% | 55% |

AECC JSC | 1% | 1% | 2% |

Tochmash VPA JSC | 1% | 1% | 1% |

Total for TVEL FC | 2.57% | 5.80% | 7.17% |

In technological processes of the enterprises of TVEL Fuel Company the produced waste could not be reused during manufacture of the key products. Non-production waste of hazard class 5 (slightly hazardous) was used in 2017 by MSZ PJSC and ChMP JSC (55% and 11% respectively).

Diagram 47

* Information is provided according to the new form No. 2-TP (waste) approved by the ROSSTAT Order No. 529 "On Approval of Statistical Tools for Organization of Federal Statistical Monitoring of Industrial and Consumer Waste by the Federal Service for Environmental Control" d/d August 10, 2017.

Diagram 48

Table 65

Indicator | 2015 | 2016 | 2017 | ∆ 2017/2016, % |

|---|---|---|---|---|

Total waste, including: | 210.1 | 176.6 | 41.6 | -76.5% |

Hazard Class I | 0.21 | 0.09 | 0.04 | -56% |

Hazard Class II | 4.08 | 0.05 | 0.02 | -59% |

Hazard Class III | 0.49 | 0.43 | 0.49 | 14% |

Hazard Class IV | 10.80 | 8.92 | 9.36 | 5% |

Hazard Class V | 194.47 | 167.1 | 31.7 | -81% |

The bulk of waste (76%) was represented by Hazard Class V (slightly hazardous) waste, such as ash slag resulting from solid fuel burning at the HPPs (Seversk branch of OTEK JSC*). Ash and slag were dumped at HPP. The bulk of other wastes was delivered to specialized organizations.

* From the first to the third quarter of 2017 SGChE JSC accounted for the waste.

Water Consumption and Water Disposal

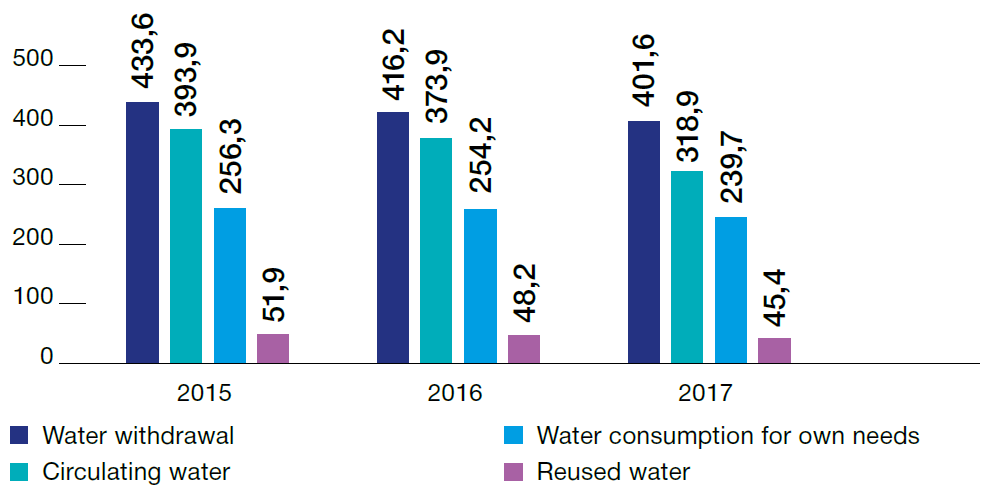

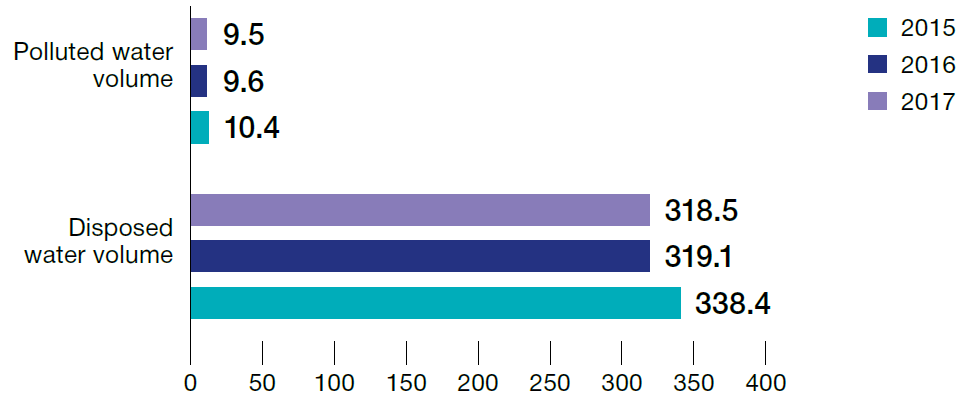

In 2017 withdrawal of water by the enterprises of the Company decreased by 4% to 402 mln m3 as compared to the previous year, water consumption for own needs decreased by 15% to 319 mln m3. Thus, 319 mln m3 of water were disposed by the Company's enterprises (55.2% of the standard). All water was disposed into natural water bodies.

Reasons for decrease in volumes of water withdrawal and consumption:

- transfer of industrial water intake of ChMP JSC to the HPP at Glazov Branch of OTEK JSC;

- measures aimed at water consumption reduction by AECC JSC;

- transfer of property complexes of HPPs at SGChE JSC, UEIP JSC and ChMP JSC to the branches of OTEK JSC.

The main source of water withdrawal is represented by natural sources 94% (379 mln m3). Water is being withdrawn by the enterprises of TVEL Fuel Company from natural sources in accordance with the set standards. Water withdrawal from public and other water supply systems was 23 mln m3 in 2017.

In 2017, the standard of water withdrawal was set at 709 mln m3, the actual volume of withdrawal was 57% of the set standard.

Diagram 49

* Actual consumption method is mainly used in calculation of water consumption indicators at the Company's enterprises.

Diagram 50

In 2017, the volume of return water was 240 mln m3. The share of return water of the total amount of withdrawn water was 60%, the share of reused water of the total volume of withdrawn water was 11%. Water consumption in the systems of return water decreased by 6%.

In 2017, the volume of disposal of polluted waste water by the Company's enterprises decreased by 1%, which is directly connected to decrease in water withdrawal.

Difference in percent decrease as compared to 2016 of water withdrawal volume and polluted waste water volume is conditioned by the fact that some TVEL Fuel Company enterprises accept waste water from outside organizations.

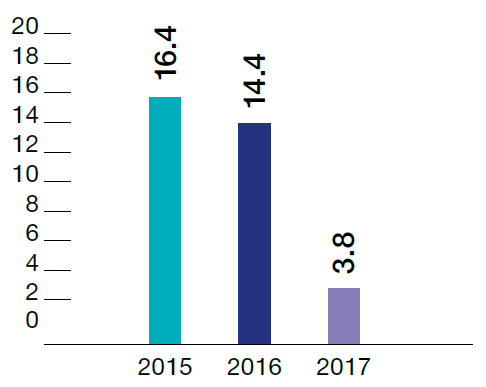

Pollutant Emissions

In 2017, total pollutant emissions into the atmosphere by the Company's enterprises amounted to 3.8 thousand tons (7% of the set standard).

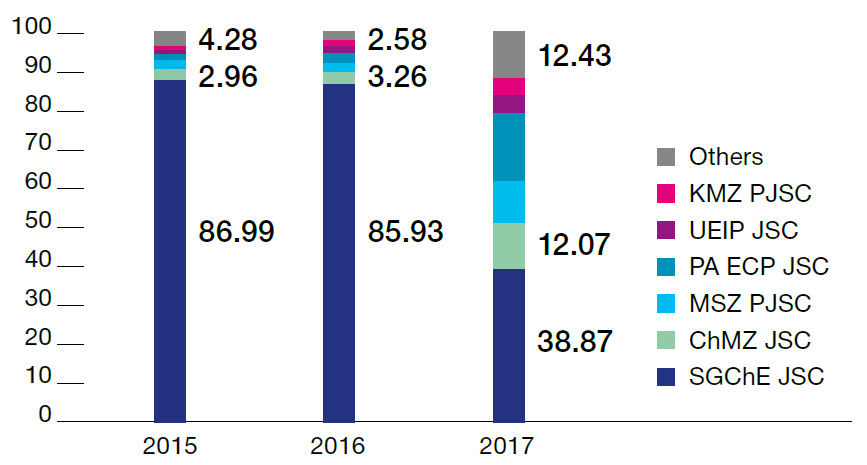

Reduction of emissions by 74% as compared to 2016 is explained by:

- reduction of burned coal fuel at HPP (Seversk Branch of OTEK JSC)*;

- transfer of property complexes of HPPs at UEIP JSC and ChMP JSC to OTEK JSC;

- production area optimization and dismantling of equipment at Tochmash VPA JSC.

* During the first three quarters 2017, HPP at Seversk Branch of OTEK JSC enjoyed the authorization for pollutants emissions of SGChE JSC.

Diagram 51

Diagram 52

Table 66

Enterprise | 2015 | 2016 | 2017 | Share of emissions |

|---|---|---|---|---|

SGChE JSC | 13.820 | 11.759 | 2.161 | 57% |

ChMP JSC | 1.776 | 1.879 | 1.397 | 37.1% |

UEIP JSC | 0.514 | 0.523 | 0.042 | 1.1% |

NCCP PJSC | 0.108 | 0.039 | 0.034 | 0.9% |

PA ECP JSC | 0.026 | 0.026 | 0.028 | 0.74% |

MSZ PJSC | 0.020 | 0.016 | 0.018 | 0.49% |

VNIINM JSC | 0.006 | 0.006 | 0.006 | 0.16% |

AECC JSC | 0.005 | 0.004 | 0.003 | 0.07% |

Tochmash VPA JSC | 0.060 | 0.055 | 0.028 | 0.74% |

KMZ PJSC | 0.030 | 0.025 | 0.026 | 0.68% |

Uralpribor LLC | 0.025 | 0.003 | 0.000 | 0.00% |

MZP JSC | 0.002 | 0.000 | 0.000 | 0.00% |

Centrotech SPA LLC | 0.003 | 0.016 | 0.027 | 0.71% |

NRDC LLC | 0.002 | 0.000 | 0.000 | 0.00% |

EDB-Nizhny Novgorod JSC | 0.002 | 0.002 | 0.000 | 0.00% |

Centrotech JSC | 0.000 | 0.000 | 0.000 | 0% |

Total: | 16.40 | 14.35 | 3.77 | 100% |

Among the enterprises of the Fuel Company the largest volumes of emissions were reported at SGChE JSC and ChMP JSC. At SGChE JSC the large portion of waste is caused by the HPP at Seversk Branch of OTEK JSC (during the first three quarters of 2017 it enjoyed the Authorization for Pollutants Emissions of SGChE JSC). It should be noted that this HPP supply heat and electricity to the settlements within the range of the enterprise location. At ChMP JSC the emissions are caused by technological processes of chemical metallurgical production.

Table 67

Substance name | 2015 | 2016 | 2017 | Enterprises |

|---|---|---|---|---|

freon-113 | 4.022 | 4.022 | 0.000 | UEIP JSC |

freon-12 | 2.46 | 2.46 | 0.000 | SGChE JSC |

2.700 | 2.400 | 2.400 | PA ECP JSC | |

72.241 | 72.241 | 72.241 | ChMP JSC | |

freon-22 | 1.222 | 1.381 | 0.776 | AECC JSC |

9.827 | 9.827 | 5.868 | UEIP JSC | |

2.592 | 2.59 | 2.590 | PA ECP JSC | |

0 | 0 | 0.900 | MSZ JSC | |

freon-13 | 164.21 | 164.211 | 164.211 | ChMP JSC |

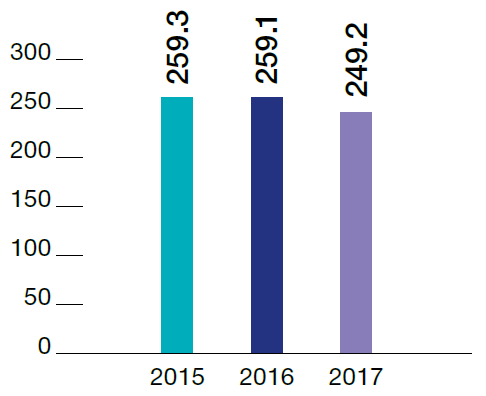

Total: | 259.28 | 259.13 | 248.99 |

Reduction of emissions of ozone-depleting substances by 4% is stipulated by:

- replacement by AECC JSC of refrigerating machines using ozone-depleting substances as refrigerants;

- transfer of refrigeration supply equipment of industrial water supply shop to Novouralsk Branch of OTEK JSC.

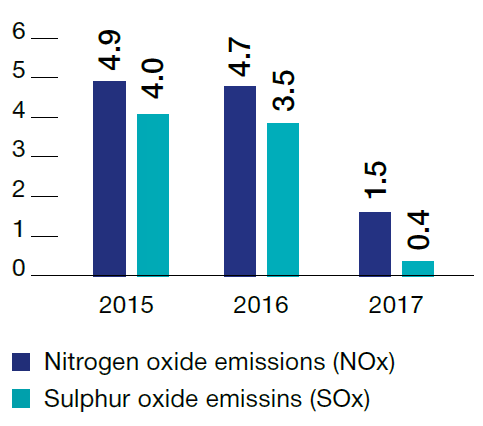

Diagram 53

* Determined by computational method along with instrumental verification.

Decrease in nitrogen and sulphur oxide emissions by 68% and 89%, correspondingly is stipulated by overall emissions decrease in TVEL Fuel Company. In 2017, emissions of solid substances amounted to 0.738 thous. tons, and volatile organic compounds – 0.502 thous. tons.

In 2017, greenhouse gas emission intensity amounted to 5.11 tons/RUB mln of revenue (in 2016 - 5.12 tons/RUB mln). The emissions from technological processes form the bulk of greenhouse gas emissions at TVEL Fuel Company.

Diagram 54

* The carbon dioxide emissions were taken into consideration to determine greenhouse gases emissions, because carbon oxide emitted into the atmosphere from anthropogenic sources is oxidized to carbon dioxide. The indicators were determined by computational method and recalculated in accordance with the Methodological Guidelines used to Quantify the Greenhouse Gas Emissions by Organizations that Carry out Economic and Other Activities in the Russian Federation, approved by the Order No. 300 of the Ministry of Natural Resources d/d June 30, 2015, namely:

- Formula No. 2 of the Methodological guidelines was used in computation.

- The amount of CO2 emissions was calculated by conversion from CO (multiplied by factor1.57).

- Emissions of CH4 (methane) of UEIP JSC and emissions of perfluoromethane (freon 14) of ChMZ JSC, subject to GWP specified in the Appendix No. 3 of the Methodological Guidelines, were also taken into account in calculating the total amount of greenhouse gas emissions at TVEL FC.

Relative Impact of the Fuel Company Enterprises on the Environment in the Regions of Presence

The enterprises included in the management system of TVEL Fuel Company are located on lands that are owned by the enterprises, as well as on lands that are used on a leasehold basis and are owned by the Russian Federation. Industrial sites of the enterprises and adjacent territories are not referred to the territories with high valued biodiversity, they are not inhabited by animals and plants included in the IUCN (International Union for Conservation of Nature and Natural Resources) Red List and the national list of protected species.

The Russian environmental legislation sets the standards of admissible impact on the environment to provide compliance with the environmental quality standards. The enterprises, in their turn, follow the standards of admissible impact of the environment, and, thus, they do not create threats to animals and plants inhabiting the areas adjacent to the enterprises of TVEL Fuel Company.

Taking into account the fact that industrial sites of the enterprises do not affect the territories with high valued biodiversity, there is no impact of activity, products and services on endangered and valuable species.

In accordance with the Russian Federation nature protection laws TVEL Fuel Company enterprises set the standards of admissible impact on the environment that ensure the environmental quality preservation. Strict compliance with the standards of admissible impact on the environment by the enterprises ensures the absence of threats to animals and plants inhabiting the areas adjacent to the Company's enterprises.

The impact of the major part of the Company's enterprises on the environment of the regions of presence is in general less than 5% of the total impact of industrial facilities on the environment of the corresponding regions. This level of exposure corresponds to the following indicators:

- AECC JSC (3.3% of waste water discharge in Irkutsk region);

- PA ECP JSC (4.9% of waste water discharge in Krasnoyarsk territory);

- SGChE JSC (0.5% of total discharge in Tomsk region).

The 5% level was exceeded by SGChE JSC (56.4% of withdrawn water, 73.7% of the total discharge of waste water in Tomsk region). The share of impact of the rest of TVEL FC enterprises in the total impact of economic activities on the environment in the regions of presence is insignificant.

The enterprises of TVEL Fuel Company have no material impact on water bodies that are used for water withdrawal. Water bodies that are used as sources of water supply of the Fuel Company enterprises are not referred to the vulnerable and are not included in the Ramsar List .

Greenhouse gas emissions at the Fuel Company are caused by technological processes. There is no significant impact caused by transportation associated with the activity of the TVEL FC enterprises, and transportation of personnel. Transportation of hazardous cargoes and special cargoes is carried out by the third parties pursuant to licenses and subject to compliance with the requirements set to organization of transportations.

For the purpose of reduction of the adverse impact on the environment, measures have been taken on scheduled replacement of morally and physically obsolescent motor vehicles with modern ones complying with exhaust toxicity standards, as well as for replacement of motor vehicles that have gas engines with motor vehicles that have diesel engines.

In operation of the rolling stock, the routes and working hours are constantly adjusted and optimized, mileage and the complement of vehicles in the motor vehicle fleet are cut down, this results in reduction of total mileage and, therefore, reduction of the total consumption of fuel and adverse impact on the environment.

The impact of TVEL Fuel Company enterprises on the climate is negligible as compared to the enterprises of the mining industry and thermal power companies. Thus, the issue related to assessment of the financial aspects and other risks and opportunities associated with climate change was not considered in the reporting period. Climate change has no impact on the activities of TVEL Fuel Company enterprises and their employees.