There are plans to increase revenue from sales of innovative products from current RUB 600 mln to RUB 7 bln by 2020, subject to successful implementation of investment projects and implementation of M&A plans.

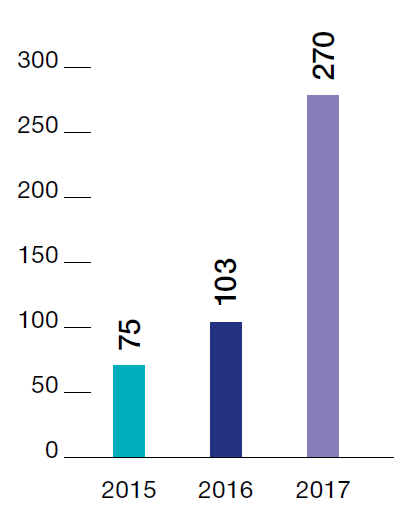

It is impossible to establish new non-nuclear production without R&D. Scope of non-nuclear businesses R&D financing is being steadily increased. In 2017 scope of works doubled as compared to 2016, and made RUB 270 mln. R&D projects are being implemented with co-financing on the part of the Ministry of Education, in 2017 the amount of co-financing made RUB 131 mln. In 2017 total amount of non-nuclear innovative projects financing reached RUB 500 mln.

Main R&D areas for non-nuclear businesses development in 2017:

- development and creation of 3D printer;

- establishment of lithium hydroxide production;

- development of equipment and centrifuge technology for REE isotopes separation;

- development of new titanium alloys and articles made therefrom;

- development of design and manufacturing technique of the long-range superconducting wires;

- establishment of energy storage production.

Diagram 19

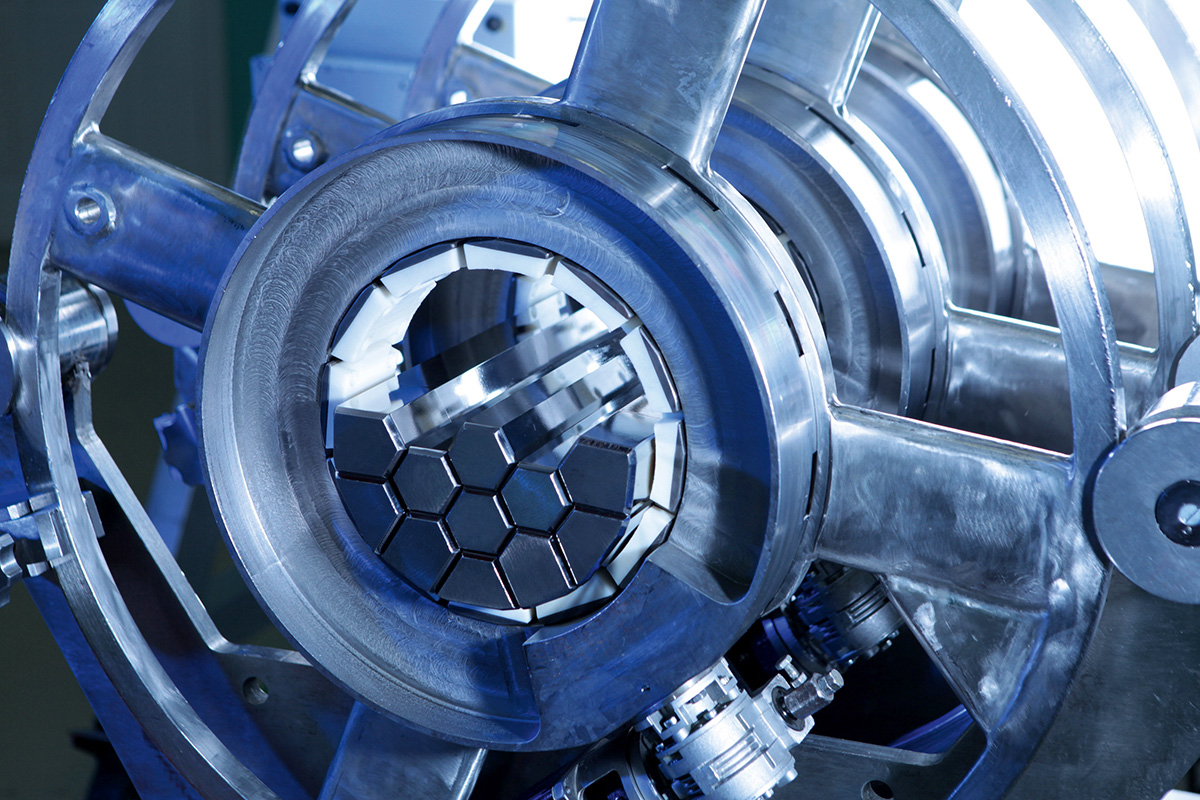

Additive Technologies

In 2015 Ural Electrochemical Integrated Plant (UEIP JSC) became the winner of the contest organized by the Ministry of Education and Science of the Russian Federation, and secured the status of the industrial partner for creation of the first Russian plant of layer-by-layer powder synthesis (metal 3D printer) together with RPA CNIITMASH JSC. The projected cost of the home-produced printer will be by 20-30% lower than that of foreign printers.

The Ministry of Education and Science of the Russian Federation is the co-funder of the project aimed at establishment of production of automated complexes of layer-by-layer synthesis of geometrically-complex metal parts (3D printer); the project is being implemented with involvement of the top higher educational institutions of Russia, enterprises of ROSATOM State Corporation.

In 2017 the unified branch integrator - RusAT LLC - was established within the group of TVEL JSC in a new business area of ROSATOM State Corporation. The integrator will ensure production and rendering of complex services in the field of additive technologies: production and delivery of materials (metal powders, rods made of different materials), 3D printers, production and delivery of articles. Growth of the global market and development of the Russian additive technologies market are the important determinants of this area. By 2025 the global market is valued at RUB 980 bln, and Russian - at RUB 61 bln. The estimated share of the integrator will be 5% and 45%, respectively.

Possibilities created by the integrator with 3D-technologies:

- manufacturing of products of any configuration and form, with complex inner structure (inside passages, etc.);

- considerable weight-saving (by 50% and more, due to removal of passive sections);

- materials saving (application of more than 95% material; during conventional machine processing - less than 30% material is used);

- savings in production mastering (twofold reduced lead time);

- savings in labor costs (labor intensity is reduced 3-8 times);

- creation of the articles with unique and improved technical parameters;

- unique combination of materials (creation of composites using materials that cannot be interfused by any other way, for instance, ceramics-metal, etc.).

MILITARY

INDUSTRIAL COMPLEX

- Production of geometrically-complex elements of special-purpose devices

AIRCRAFT

INDUSTRY

- Production of elements for aircraft engines

ENERGY

INDUSTRY

- Production of turbine blades

MACHINE

BUILDING

- Production of geometrically-complex elements of different structures

Results 2017:

Production of metal powder samples for 3D printer with the quality exceeding the foreign analogues. Decision-making concerning improvement (together with Centrotech SPA LLC) of powder production plant with a view to apply additive technologies internationally on an industrial scale.

The pilot model of metal poly-powder 3D printer of the second generation of 3D printers, developed by ROSATOM State Corporation, was assembled in November. Print modes of the assembled 3D-printer are being adjusted.

It is planned that in 2019 a high-tech production for 3D printers assembly will be established at Novouralsk site of TVEL JSC; this will additionally create nearly 30 jobs.

Plans 2018:

- Development and presentation of the integrator development plan, provision of the integrator activity funding.

- Development of the product line.

- Preparation of the intra-branch list of articles that can be produced with application of additive technologies.

Additive technologies for gas turbine engines

In July 2017 TVEL JSC presented at the International Aviation and Space Show MAKS-2017 the unique development by Grigory Shanin, the student of the Bauman Moscow State Technical University.

The prototype of gas turbine low-thrust engine developed by Grigory Shanin during his studies, with support of TVEL Fuel Company of ROSATOM, was selected for competition of innovative youth ideas, and in 2017 was admitted the winner at the final stage of Young Professionals Tournament "TeMP" of ROSATOM State Corporation.

The design of gas turbine low-thrust engine for unmanned aerial vehicles was improved with additive technologies: 70% of elements are produced using layer-by-layer technique. Gas turbine plant can be in demand on the world and the Russian UAV market. As compared to the competitors, the prototype has fuel efficiency improved by 40% and tenfold increased operation life.

The technological groundwork, laid at development of the prototype of gas turbine low-thrust engine, became the foundation of new investment project opened by TVEL JSC. The Company intends to start pre-test assembly program of engines at one of its sites.

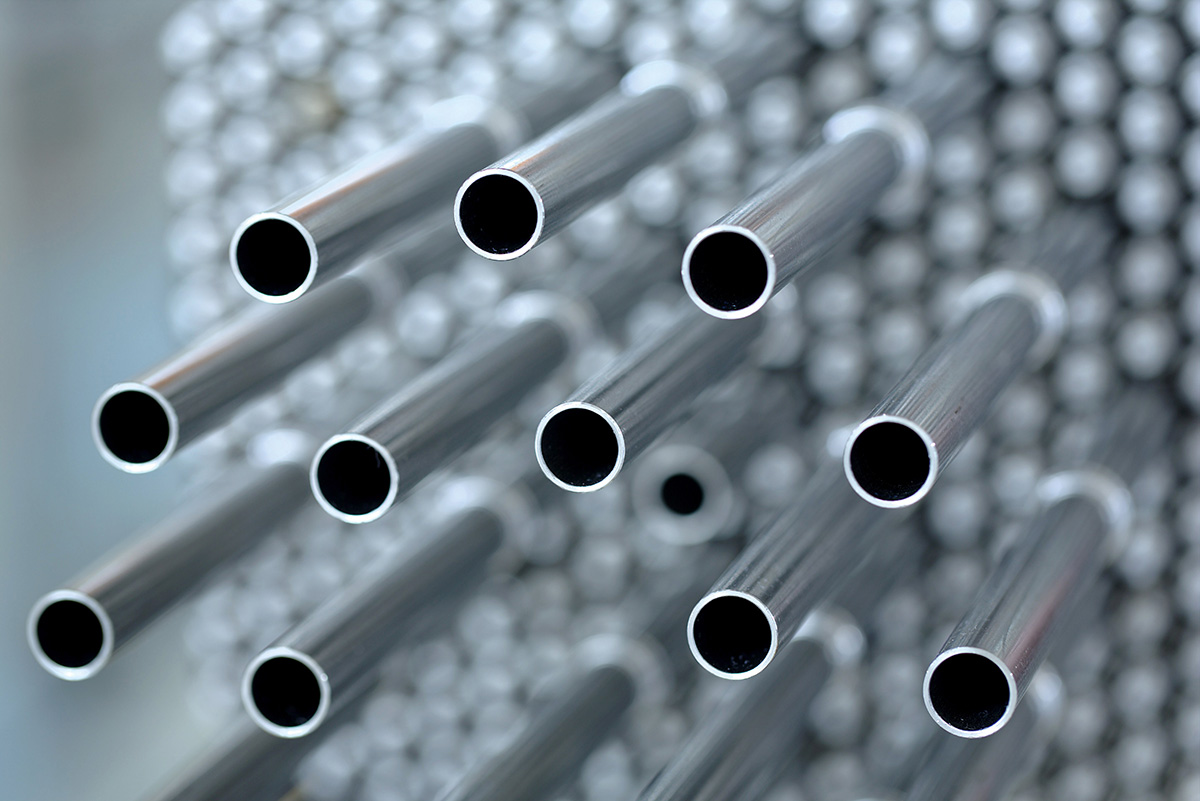

Superconductors

In furtherance of the competences in the area of low-temperature superconductors, TVEL Fuel Company continues the development of design and manufacturing technique of wires for the project of the European Centre for Nuclear Research (ECNR, Switzerland) on creation of FCC (Future Circular Collider), and for magnetic systems of high-energy physics facilities, and for other applications.

In 2017 the design and experimental technology for production of Nb3Sn-based superconducting wire were developed at the request of ECNR for the project on improvement of the existing LHC collider. The wire was designed based on "internal tin source" method. Pilot lot of wire has been sent to ECNR for tests and experimental cable manufacturing.

It is planned that in 2018 the required wire characteristics for FCC will be achieved with the experimental samples. Conclusion of the contract with ECNR for production of qualification batch of superconducting wire is planned for the first half of the year. VNIINM JSC is the developer of design and technology, and ChMP JSC is involved in production of the pilot batches and technology elaboration. The world leading companies from the USA, EU, Korea, Japan and China are also engaged in development of wire for FCC project. At the moment neither company has reached all combined characteristics of superconducting wire set by the requirements of ECNR for FCC project. It is planned that the required characteristics will be attained by 2020.

Other types of low-temperature superconductors - NbTi-based wires - are required for creation of modern medical equipment, primarily MRI-scanners.

In June 2017 VNIINM JSC received the utility model patent "Superconducting composite magnesium diboride based (MgB2) wire". Magnesium diboride based wires can be applied to create magnetic systems of medical tomographs, where traditionally there are applied superconductors based on NbTi alloy, and also for wind machines and complex power lines with simultaneous transmission of electricity and refrigerating agent (liquid hydrogen) in one pipe.

Possibility of operation under conditions of refrigeration with liquid hydrogen, neon, helium vapors and cryocoolers, and relative low price of base materials are the advantages of magnesium diboride based superconductors over conventional low-temperature superconductors (Nb3Sn and NbTi).

Additive technologies for FA

In August 2017 VNIINM JSC formed the work team for development of the pilot technology of 3D-printing of FA end pieces. The capabilities of additive technologies will be used in nuclear industry for production of elements for all types of FA. First of all, these are the end pieces: heads, bottom nozzles, support grid, anti-debris filters. These articles are difficult-to-make using the existing methods, application of 3D-printing will make it possible to produce articles with unique design.

To use the specified advantages, the characteristics of wire, attained by now in the world production, must be essentially improved. That is why MgB2 based superconductors are not used widely in electrical equipment, and their application is limited to pilot and demo units with low magnetic field (<5 T) and temperatures up to 15-20 K.

At present high-temperature superconductors are considered as base materials for application in the wide range of electrotechnical devices. Current limiters, power transmission cables, transformers, electric propulsion systems, energy storage units - this is the incomplete list of devices where application of high-temperature superconducting materials may lead to significant improvement of performance characteristics as compared to conventional devices (decrease of weight and size, improvement of network reliability, etc.).

"Applied superconductivity" has been determined as branch-wise strategic technological direction that includes development of high-temperature superconducting (HTS) materials and HTS-based devices, including with involvement of the enterprises of TVEL Fuel Company.

High-Tech Steel

In summer 2017 the scientists of VNIINM JSC represented the development result of high-tech steel EK-181 (RUSFER-EK181) for the cores of nuclear and fusion reactors with liquid metal coolant with operation temperature up to 700 degrees.

Its advantages include high-temperature strength, heat and radiation resistance, rapid activity decay. Application of steel will make it possible to improve neutronics of reactor cores due to decrease of parasitic neutron loss, and will ensure reduction in expenses for RW disposal and burial.

In the course of elaboration and commercial development of steel EK-181, VNIINM JSC created materials knowledge bases for stress-strain, thermal and nuclear-physical properties of low-activated structural materials. The research results are protected by two patents and nine "know-hows", more than 40 articles have been published in refereed journals.

Quartz Сoncentrate

In July 2017 AECC JSC and German company QSIL GmbH signed the legal binding documents on establishment of joint venture Quartz LLC for production of high-purity quartz concentrate. Share of QSIL GmbH in the project will make 60%, share of AECC JSC - 40%. Production facilities will be created at AECC JSC industrial site. Total amount of investments in the project is estimated at RUB 600 mln, including initial contributions of shareholders to the authorized capital of the enterprise, scheduled recapitalization and funds raising.

The project implementation will allow creation of international industrial cooperation in vertically integrated production chain. New enterprise will use hydrothermal synthesis to grow synthesized high-purity quartz crystals out of the gangue quartz mined in deposits of the Polar Urals and Irkutsk region; then the crystals will be reprocessed into high-purity quartz concentrate. The whole output will be delivered to Europe on QSIL enterprise, the world leading manufacturer of articles out of quartz. In particular, high-purity quartz sand, produced in Irkutsk region, will be used to manufacture quartz glass, which is widely used in semiconductor industry for production of processors, computer memory devices, etc.

The project complies with the principles of the Uniform Industry-Specific Policy for development of new businesses of ROSATOM State Corporation, and is intended to address the strategic objective for development of the second industrial core due to the market launch of new export-oriented products. New enterprise can hold 2.5% of the world market of high-purity quartz concentrate, and in future can increase this share to 10%.

The start of pilot batch production is scheduled for 2018. Launch of production line is scheduled for 2021, initial production output will be 250 tons/year. The enterprise will create 50 new jobs.

Titanium Dioxide

In 2017 the project company "Sibirsky Titan" LLC was established for the purposes of joint implementation of the project on production at the industrial site of SGChE JSC of the import-substituting titanium dioxide, which is widely applied in paint-and-varnish industry. The investors are SGChE JSC and Davinchi Holding Company. Completion of equipment installation and start of pre-test assembly program are scheduled for 2018.